In manufacturing, procurement plays a crucial role in determining the success of the entire project and deciding whether the customer will receive the product on time.

The procurement process is different for various manufacturing types. The more the complexity of the manufacturing process, the more complex the procurement process becomes.

For example, in Make-to-order (MTO) manufacturing, material purchases are initiated to keep the inventory levels at prescribed optimum levels. The reorder points are constantly adjusted so that there is no sudden dip in inventory levels. The main challenge MTO manufacturers face is to procure the right material at low costs from the right supplier at the right time.

in Engineer-to-order (ETO) manufacturing, the purchases are determined based on the actual requirement and it varies as the project progresses. This is because an ETO manufacturing project is subjected to changes at all times thereby impacting the material/stock requirement. The main challenge lies in handling ever-changing customer needs and accordingly, making changes to stock requirements with suppliers. Of course, all of this needs to be done in a cost-effective and time-intensive manner.

What challenges do ETO manufacturers face in procurement?

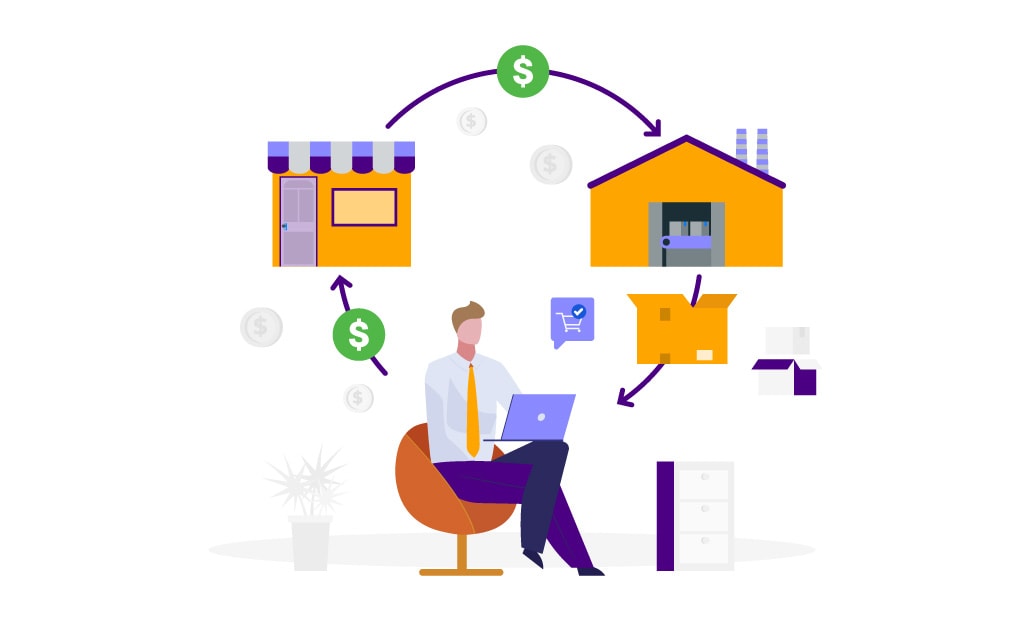

ETO manufacturing runs on the principle of a pull system, where products are manufactured based on the customer’s requirement. It is the opposite of the push system in conventional discrete manufacturing where the products are manufactured in bulk and sent to retailers for further sales. Here, inventory procurement is entirely based on production planning that is derived from the sales forecast and customers’ consumption behavior.

In the ETO environment, the pull system poses a challenge as the material and parts requirements are not known in the beginning. It is only after the design and BOM creation stage, that the actual requirement is known. Considering that the production stage is very close, it becomes a tricky situation as the manufacturer has to procure the required materials and tools at lightning-fast speed from their suppliers, that too at the best price. Also, with multiple iterations of the product design and BOM, manufacturers have to ensure that suppliers are flexible enough to deliver the necessary goods.

To tackle this challenge, manufacturers need to have a robust, real-time communication platform with their suppliers. Constant exchange of planning and requirement data right from RFQ to Sales to Design to Delivery ensures that all stakeholders have the same information in real-time enabling them to take swift decisions.

How does ERP help solve these challenges?

ERP software has various in-built capabilities for sales, procurement, inventory, supply chain management, and communication that are designed for ETO manufacturers. Entire datasets can be entered, accessed, stored, and modified in a centralized database, thereby enabling real-time access to all stakeholders.

For example,

- ETO manufacturers prepare quotes solely based on historical data of similar custom orders. However, an ERP enables them to share quote estimates with their suppliers to get an accurate estimate before dispatching to the customer.

- Manufacturers can exchange critical sales, purchase, and inventory data with their suppliers in real-time with the help of ERP’s in-built Electronic Data Interchange (EDI). They can share information pertaining to orders, releases, ASNs, and invoices with their suppliers and even customers instantly.

- An ERP allows manufacturers to provide real-time access via self-service portals to production and inventory data to approved suppliers. With this, suppliers can access purchase orders, product configurations, BOM, invoices, payment, sales forecasts, demand details, etc.

- Manufacturers can share preliminary BOM with its complete hierarchy and break up with suppliers.

- With an ERP, design, and BOM workflows are automated. When the BOM is finalized, work orders are generated to manufacture/procure necessary parts, and RFQs/POs are placed with respective suppliers immediately from within the ERP.

- Once the orders are placed and the shipment arrives, manufacturers can cut down goods receiving time by recording goods info printing bar-code labels using portable printers, and scanning the data using bar-code devices. They can also generate receiving documents and expedite the entire process.

- They can also instantly update the goods procured data into the BOM.

Conclusion

With capable ERP software, ETO manufacturers can automate purchasing management workflows and reduce significant time, cost, and manpower. They can keep track of every transaction and communication thread in the ERP and ensure there is no missing information or data. Time is of the essence in ETO manufacturing and an ERP ensures that the materials are ready for production from suppliers when it is needed.

Contact us for a Demo of OmegaCube ERP for ETO manufacturers.