Engineer to Order (ETO) is a manufacturing approach that is highly driven by customer demand and is highly flexible. Customers opt for ETO manufacturing when they need a product tailor-made to suit their requirements or want to transform a concept into a final product.

ETO manufacturers have in-depth knowledge and expertise to understand customer requirements and transform them into fully functional products from conceptualization to the final product. ETO manufacturing is more prevalent in the B2B segment compared to the B2C segment.

Examples of ETO Manufacturing

There are many examples of ETO manufacturing. The common ones are,

- Heavy industrial machinery and equipment (powerplant equipment, boilers, electrical equipment, commercial HVAC equipment, industrial and construction cranes, etc.)

- Components for large man-made structures (bridges, buildings, skyscrapers, etc.)

- Aeroplanes, drones, helicopters, and associated parts/equipment

- Customized vehicles for specific purposes

How does ETO manufacturing work?

Unlike conventional, discrete manufacturing, ETO manufacturing involves highly iterative processes that are design oriented and client-centric. There is a lot of creativity involved as engineers try to convert clients’ concepts into reality through continuous collaboration right from design to delivery.

Simply explained, a generic ETO process involves,

- Niche/customized product requirements by the customer to the ETO manufacturer.

- Product research and design by the engineering team in continuous collaboration with the customer.

- Design review by the customer followed by changes if any. In case there are no changes, the design is approved by the customer.

- Production planning and manufacturing by the production team.

- Quality checks and shipping of the final product to the customer.

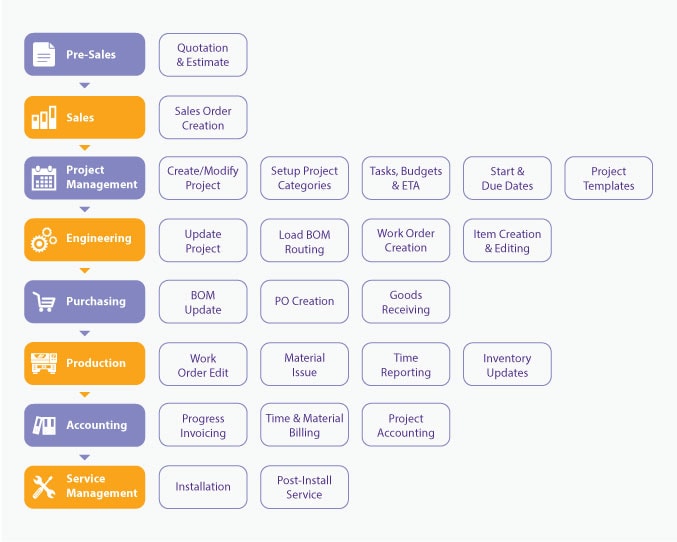

As easy as it sounds, ETO manufacturing involves a lot of complex processes that require complete support and collaboration of all departments, third-party vendors, and the customer. The below flowchart illustrates the end-to-end ETO manufacturing process.

A typical Engineer-to-Order (ETO) Workflow

Pre-Sales

Every customer order begins with a Request for a Proposal (RFP) from the customer followed by a proposal, quotation, and sales order creation. This phase takes up immense time and resources due to the involvement of multiple departments.

Sales Order

After the customer approves the proposal, a sales order is created that includes the cost as per the shared quotation, design-to-delivery time, rework & scrap costs, and the entire Work Breakdown Structure (WBS).

Project Management

A project management team is a vital department that successfully drives the entire project from start to finish. A project manager is an important link between the ETO manufacturer and the customer. The PM team oversees and manages end-to-end project-related activities from sales order creation to product delivery to the customer.

Design

This is the most crucial and time-intensive phase of the project where design engineers and the customer collaborate to transform the initial concept into an actual design. This is a continuous, iterative process and the design goes through innumerable changes before it is finalized and passed on to the production phase.

Product Configuration

Product configuration plays a major role in ETO manufacturing as custom products require a different quotation and price estimation approach. For each product, BOM configuration, sales pricing, discounting, machine, material, and labor capacity needs to be decided and configured from scratch. To reduce the quotation cycle, manufacturers can use pre-decided templates to quickly arrive at accurate quotes and price estimates using the product configurator tool.

Procurement

During the design stage, the design team creates a detailed Bill of Materials (BOM) that encompasses all parts, assemblies, and sub-assemblies. Based on this BOM information, the procurement team places a purchase request with preferred suppliers/sub-contractors to procure the required materials well in advance. For each part/component to be manufactured, the engineering team plans and creates work orders in advance. PO creation is expedited for the materials to arrive on time. Goods receiving and quality control processes are kept in place to ensure adequate documentation and optimum quality materials.

Production

The production team finalizes the production schedule, labor, machine, and material availability for the manufacturing/assembly to begin. They initiate shop-floor operations and track them at each manufacturing phase. Work orders are continuously updated to ensure production happens in clockwork precision. Inventory levels are constantly updated and monitored to prevent shortfalls. Timesheets are updated and tracked to ensure maximum labor utilization. The maintenance team is always on standby to prevent breakdown/idle times. The production team also keeps contingency plans and adjustments in place to face probable product design changes that might arrive during the manufacturing phase.

Accounting

The accounting team works in tandem with the production team to carry out progress invoicing after the completion of each manufacturing phase as per the production plan. The team also keeps a track of project expenditures and derives trends to see whether they exceed the budget. Time and expense billing are collated and also accounted for.

Product Delivery & Installation

This is the most critical phase of the project. The manufacturing team ships the components, assemblies, and sub-assemblies to the customer’s location and does the necessary installation. The product is comprehensively tested and necessary steps are taken to resolve any errors or deviations.

Service Management

Post-installation, the manufacturer takes the necessary steps to resolve any issues that arise during the initial product operation. This can be related to a particular component or a sub-assembly and will have to be repaired or replaced at the earliest.

Apart from this, the manufacturer also conducts intense training sessions for personnel who will operate the machinery. Standard Operating Procedures (SOPs), user guides, maintenance documentation, and emergency response steps are handed over to the customer at the time of product delivery.

The manufacturer usually takes care of the maintenance through AMC agreements with the customer.

Project Closure

The project is deemed completed as soon as the customer makes the final payments against the invoice generated by the manufacturer.

OmegaCube ERP’s advanced functionalities automate Engineer-to-order (ETO) Manufacturing workflows and make it more profitable to run an ETO business.

One Response

Just exploring your services