- OmegaCube Technologies

- Solutions

- By Industry

- Aerospace and Defense

Aerospace and Defense

Key Benefits to Aerospace & Defense Manufacturers

- Control your A & D units from one place with our centrally managed database that enhances performances, optimizes resource usage, and increases process efficiency.

- Lay accurate plans, automate tasks, customize execution schedules and dynamic planning based on most current demands using Planning & Scheduling.

- Enhance the end-product quality, avoid delays, errors, and Cost of Poor Quality (COPQ) with efficient Quality Management.

- Get accurate, instant updates on material location, where your lot has been docked, or the warehouse that has the material you need with Lot Management and Material Traceability.

- Save costs, forecast potential losses, and take quick steps to resolve any upcoming cost crunches with Cost Management.

Top Functional Areas in OmegaCube ERP for Aerospace & Defense Manufacturers

- Continuously monitor on-time material and component availability throughout the supply chain, and get alerts for immediate action to reduce risk.

- Measure actual lead times vs. planned lead times to adjust planning parameters, and improve planning effectiveness and reliability.

- Assess the quality risk of items that are in QA hold and adjust the planning accordingly.

- Track non-conformance through a centralized database integrated with RMA, Shop Floor transactions & Inventory.

- Analyze quality metrics for suppliers, parts, manufacturing, and operations using quality management dashboards.

- Assign tasks, generate automatic emails/reminders, and document corrective & preventive action using 8D methodology.

- Keep a track of customer-approved vendors for both material and outside processes for each item.

- Place purchase orders only to approved vendors based on work order requirements.

- Attach material certifications to inbound material lots and track the lots throughout the process.

- Effectively track on-time delivery and quality performance of vendors.

- Track all project costs and consolidate them into a project ledger.

- Track actual costs as the material are procured, utilize in posting to work in progress, and finished goods.

- Track detailed breakdown for part costs – material, overhead, labor, outside process, etc.

- Track date, time-stamp, and personnel for transactions entered and track changes to actual field data for a specific period.

- Track real-time inflow & outflow of inventory and gain greater visibility of the entire supply chain.

- Gain complete visibility to document life-cycle along with time stamps & personnel details.

- Link workflow and design documents to BOMs, inventory, supply chain, and customers.

- Have a complete view of in-process jobs on the shop floor along with their status with Shop Floor management

- Go paperless with complete documentation and revision control management along with auto-approvals and auto-updates

- Electronically transact with your trading partners for order status, releases, ASN & invoices.

- Avoid intermediary portals and get auto-updates about the latest happenings at the customer’s or vendor’s end.

- Maintain EDI formats in-line with your trading partners through on-premises or online EDI translation packages.

- One-click access to job planning and progress for improved customer service.

- Effective Engineering Change controls with both customer revisions and internal process version tracking.

- Internal approval management from each department with their own checklists and targeted timelines to effectively collaborate during new project development or ECN releases.

- With revision control, manage overall documentation (product designs, workflow documents, etc.), and get complete visibility to document life-cycle with time stamps & personnel details.

- Continuously monitor on-time material and component availability throughout the supply chain, and get alerts for immediate action to reduce risk.

- Measure actual lead times vs. planned lead times to adjust planning parameters, and improve planning effectiveness and reliability.

- Assess the quality risk of items that are in QA hold and adjust the planning accordingly.

- Track non-conformance through a centralized database integrated with RMA, Shop Floor transactions & Inventory.

- Analyze quality metrics for suppliers, parts, manufacturing, and operations using quality management dashboards.

- Assign tasks, generate automatic emails/reminders, and document corrective & preventive action using 8D methodology.

- Keep a track of customer-approved vendors for both material and outside processes for each item.

- Place purchase orders only to approved vendors based on work order requirements.

- Attach material certifications to inbound material lots and track the lots throughout the process.

- Effectively track on-time delivery and quality performance of vendors.

- Track all project costs and consolidate them into a project ledger.

- Track actual costs as the material are procured, utilize in posting to work in progress, and finished goods.

- Track detailed breakdown for part costs – material, overhead, labor, outside process, etc.

- Track date, time-stamp, and personnel for transactions entered and track changes to actual field data for a specific period.

- Track real-time inflow & outflow of inventory and gain greater visibility of the entire supply chain.

- Gain complete visibility to document life-cycle along with time stamps & personnel details.

- Link workflow and design documents to BOMs, inventory, supply chain, and customers.

- Have a complete view of in-process jobs on the shop floor along with their status with Shop Floor management

- Go paperless with complete documentation and revision control management along with auto-approvals and auto-updates

- Electronically transact with your trading partners for order status, releases, ASN & invoices.

- Avoid intermediary portals and get auto-updates about the latest happenings at the customer’s or vendor’s end.

- Maintain EDI formats in-line with your trading partners through on-premises or online EDI translation packages.

- One-click access to job planning and progress for improved customer service.

- Effective Engineering Change controls with both customer revisions and internal process version tracking.

- Internal approval management from each department with their own checklists and targeted timelines to effectively collaborate during new project development or ECN releases.

- With revision control, manage overall documentation (product designs, workflow documents, etc.), and get complete visibility to document life-cycle with time stamps & personnel details.

Enterprise solution for every industry

Our Customers are Our Purpose and Our Strength

People expect that an ERP system will allow them to run their business exactly how they want to, but more often than not, the ERP system is the glove and you’re the hand that has to squeeze into it.

Not so with OmegaCube. They helped us meet our vision rather than requiring us to formulate our processes around their solution.

There were competitors who weren’t as flexible as OmegaCube. OmegaCube assured us that they can do whatever we want them to do and they can adjust to fit our organization and not the other way around. They provided us insights into what they did for other customers and we saw what work they have done for them. This was, eventually, the final selling point for us.”

This was March 2020 and then COVID-19 hit. If we were still using the old FoxPro system and the manual way of operating, I don’t think we could have had everybody go home and work remotely.

With OmegaCube ERP, we were able to work remotely and still operate during the pandemic. Even though we just completed setting up our initial ERP system, our employees were able to run with it while working remotely and that ended up working out great. The system operated efficiently for sales, engineering, and purchasing.

I don’t think we could have done that with the old FoxPro system as we did with OmegaCube ERP. So the timing of implementing OmegaCube ERP was perfect.

Browse through our Latest ERP and Technological Insights

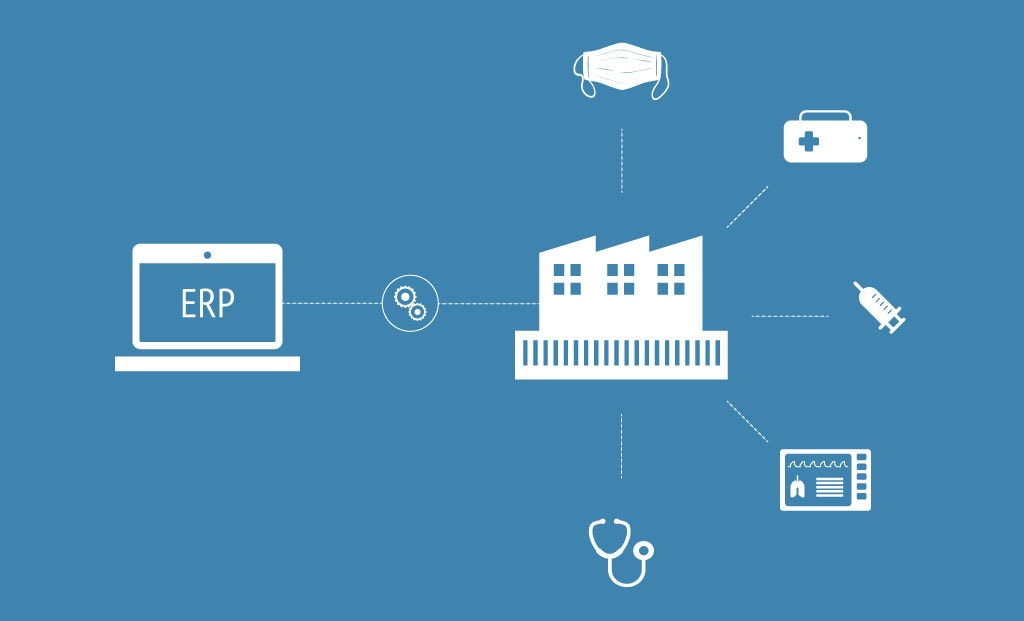

How ERP helps Medical Equipment manufacturers to operate round the clock (in times of COVID-19)?