The manufacturing industry is much more competitive and aggressive in their approach owing to volatile economy, market-dynamics and increased globalization. Many manufacturers are now focused on adopting a lean production model by investing in innovative technological practices that enable them to produce quality products at a faster pace. At the same time, enabling them to reduce overhead costs and tackle the biggest issue they collectively face, material savings.

Apart from the challenge of procuring the right amount of material at the right time and tracking its movements along the supply chain, the bigger challenge is to optimize its utilization during production and ensure minimal to negligible wastage.

In metal manufacturing, specially in Small & Medium Enterprise (SME) segment, a manufacturer deals with multiple orders with varied requirements. Most of them are one-time orders and each order differs from each other in terms of requirements, part specifications, dimensions, quantity etc. Managing these and ensuring timely production with optimum utilization of resources is something that each manufacturer looks forward to. Let us see how an ERP software with the help of a Nesting Software achieves this in a seamless and cost-effective manner.

Introduction to Nesting

Nesting is a manufacturing process where parts are cut from flat sheet raw materials in the most efficient manner possible, thereby reducing material wastage to the maximum. Parts are cut using laser, plasma, waterjet, oxyfuel technologies etc. This process is executed with the help of a Nesting Software that directs the cutting machine to cut the required parts from the material sheets.

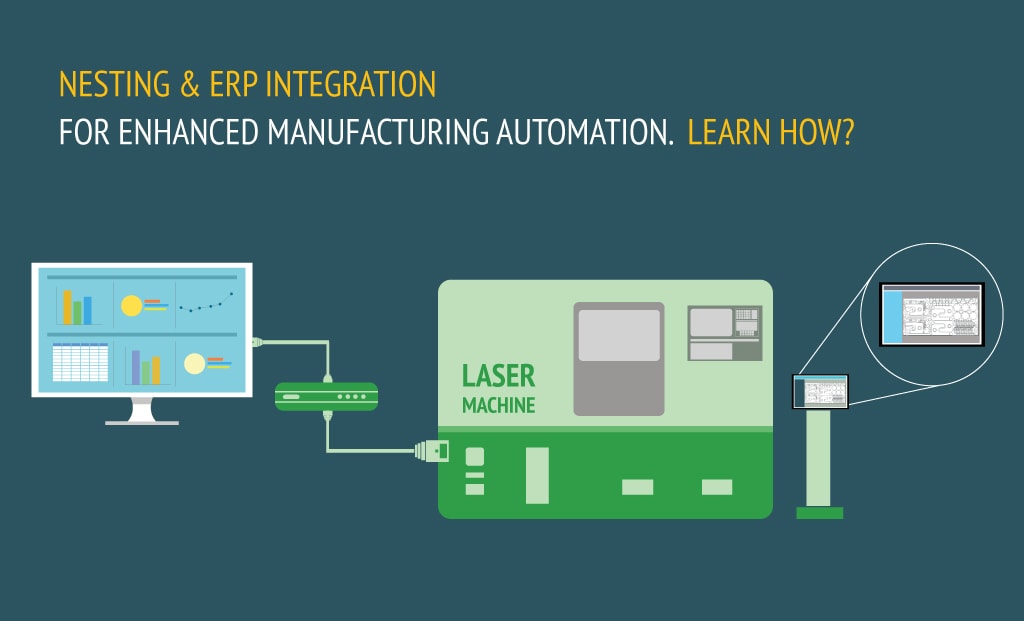

The entire process becomes more faster and efficient when a Nesting software is integrated to an ERP. An ERP has the capability of integrating with various nesting applications such as ProNEST, SigmaNEST etc. It uses its Order Management and Shop Floor Management system to generate/push data to the Nesting software for the parts to be cut efficiently. Also, the Nesting software have the capability of updating the ERP with parts cut information, material utilization etc.

There are various ways where an ERP and Nesting software can communicate with each other and ensure smooth nesting workflow. Let’s have a look at these.

| ERP to Nesting Communication | Nesting to ERP Communication |

| Manual Operation | |

| Here, each order details such as quantity of parts, part number, order number, order due date etc. are entered into the Nesting software manually. The material to be cut is selected and tagged along with single or multiple order numbers. Each order is given a priority by the operator based on the production due date. | Post-cutting of parts, the operator updates the parts cut information, materials consumed, order completion status in Work Order of the ERP. |

| Conclusion Manual information updates on ERP and Nesting software consumes immense amount of time. Also there is scope for human error leading to material wastage and consequent delay in production. | |

| File Transfer between ERP and Nesting Software | |

| The operator exports related Work Order(s) from ERP as an XML file and imports them into the Nesting Software. The software accordingly creates tasks and provides an overview of how each task will look like. The layout can be modified by the operator for optimum material utilization. | Post cutting of parts, the nesting software is updated with information such as parts cut and materials consumed. This information is then exported from the nesting software in the same file format and imported to the ERP for updates to the Work Order. |

| Conclusion The ‘File Transfer’ process between the ERP and Nesting Software brings some amount of automation to the entire workflow. However, human intervention is still needed but only to import/export the files between the software and ensuring the information update is accurate. The scope for manual errors are largely reduced. | |

| ERP & Nesting Software Database Integration The nesting software is integrated with the ERP for a more seamless cutting operation and continuous updates to the work orders. | |

| The nesting software is integrated with ERP for a more seamless cutting operation. The nesting software checks for new orders entered in the ERP that require material cutting. The ERP sends part requirements and available material inventory to the nesting software. Based on the order-due date, the software prioritizes each order or combines multiple hot orders in a single nest layout. The nesting software automatically modifies the nesting layout for optimum material utilization and carries out the cutting process. | Post-cutting, the nesting software updates the ERP with parts nested, materials consumed, order status etc. Based on this, the ERP reduces the inventory levels and updates the Work Order with nesting details, parts cut information, material costs/order etc. User input about parts cut can also be directly entered into an ERP screen and automatic updates of work order, material consumption is performed by ERP. |

| Conclusion The complete automation of Nesting and ERP software eliminates manual processes and redundant tasks from the workflows. The constant interaction between the two system ensures more shop-floor visibility and faster production. A bit of human intervention is needed to monitor the processes and ensure no disruptions happen within the software and machine interface. | |

Automating nesting workflow has become a must for manufacturers as it is a core production area affecting vital manufacturing parameters i.e. time, material and money. If implemented correctly, it brings operational efficiency, increased profitability for manufacturers, and faster production leading to satisfied customers.

One Response

Just exploring your services